Turbidity Sensor TC Series

Turbidity Sensor TC Series

Product Name

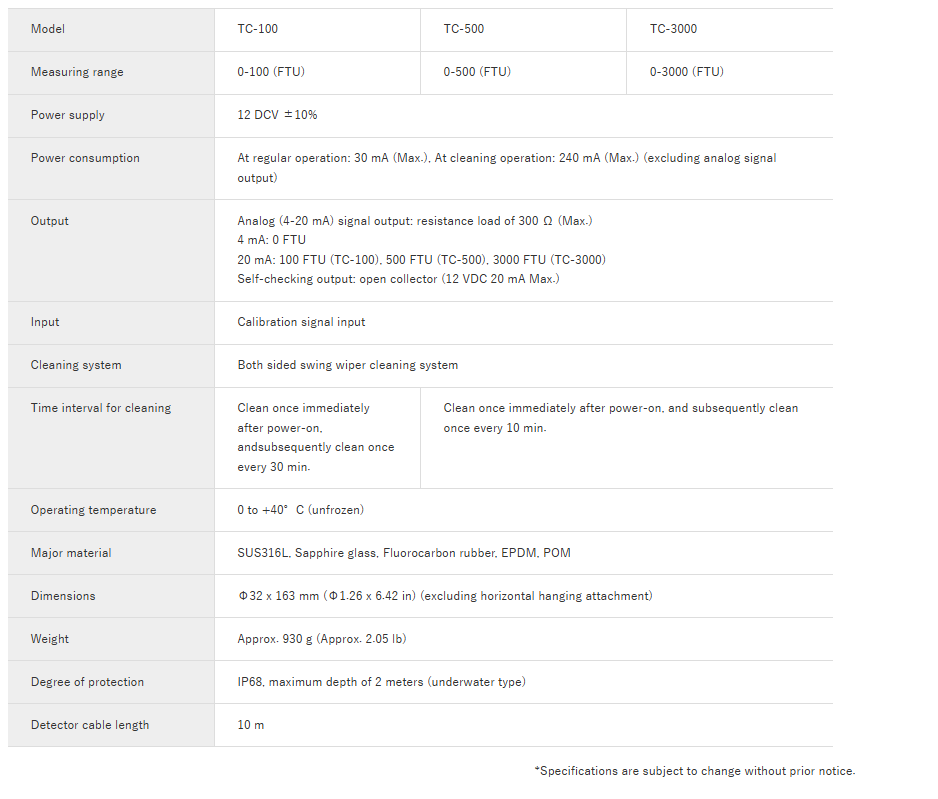

- TC-100 [Sensor],[Parts No. 05035]

- TC-500 [Sensor],[Parts No. 05036]

- TC-3000 [Sensor],[Parts No. 05049]

Feature

- The built-in wiper system effectively keeps the lenses clean.

- The optical windows are made of scratch-resistant sapphire glass, which is easy to clean.

- Its compact design allows for easy integration into any installation site.

- Continuous measurement is possible with a single sensor. The built-in analog output (4 to 20 mA) enables data transmission to various devices, making it adaptable to a wide range of applications.

The TC-100/500/3000 series turbidity sensors are compact, analog-output sensors designed for a wide range of applications. Each model is optimized for a specific measurement range, allowing users to select the most suitable sensor based on their application requirements.

- Built-in wiping cleaning system certainly keeps lenses clean. Check and clean the window surface once every month.

- The optical windows are made of scratch-resistant sapphire glass, allowing for easy cleaning and scrubbing without damage.

- The compact design allows for flexible installation in virtually any location.

- Continuous measurement is possible with a single sensor. The built-in analog output (4 to 20 mA) enables data transmission to various devices, making it adaptable to a wide range of applications.

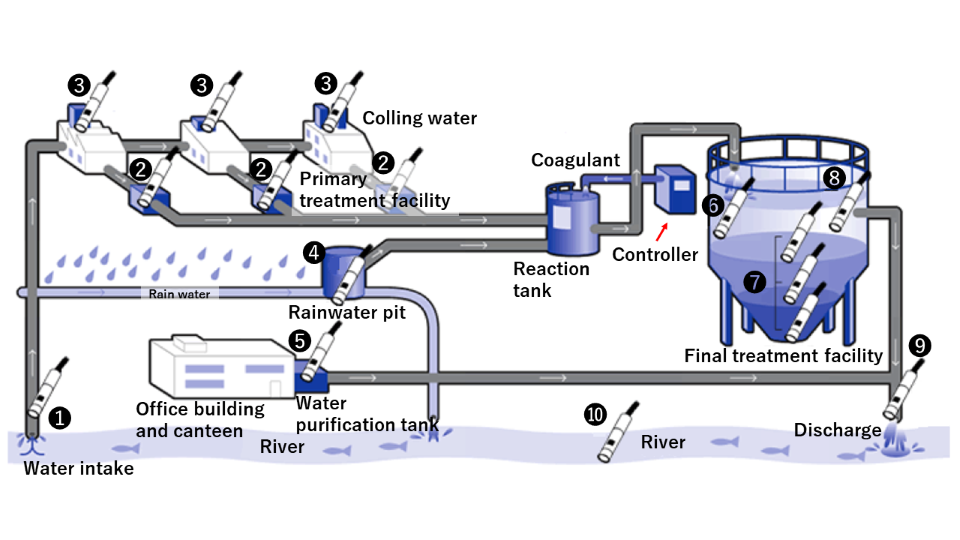

The TC-100/500 sensors can be installed at multiple locations across the factory, offering flexibility for various monitoring points.

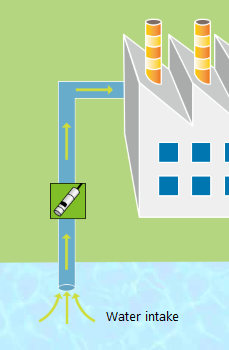

1) Monitoring the acquisition of water used in factory processes

Monitoring turbidity upon water intake helps prevent issues caused by sudden changes in turbidity later in the process.

2) Turbidity monitoring at every stage of the manufacturing process

This makes it easier to pinpoint the source of any issues that arise during wastewater treatment. By monitoring the primary treatment facility, the operation of the final treatment stage becomes more stable and efficient.

3) Monitoring Turbidity Levels at the Cooling Tower

Turbidity monitoring after applying a cleaning agent enables control of the water filtration system and adjustment of the blow water volume based on turbidity levels.

4) Rainwater pit

This allows valve control to deliver only high-concentration initial rainwater to the treatment facility and run water into the river at the point treatment is no longer needed.

5) Monitoring of Drainage Outside the Manufacturing Process

We can achieve total management of a factory's wastewater by monitoring not only the water used in the manufacturing process but also that used in the purification tank, etc.

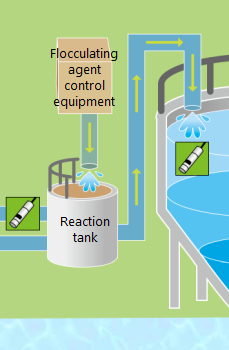

6) Coagulant control

Accurately determining the concentration of wastewater allows for precise dosing of cleaning agents, ensuring stable and consistent water quality.

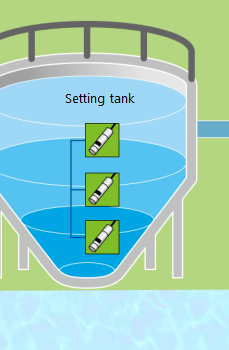

7) Sludge-Water Interface Monitoring

Attaching a sensor to the settling tank enables monitoring of the sludge interface. Installing sensors at two or three different depths provides a more accurate and detailed view of the sludge-water boundary.

8) Monitoring of sludge overflow

This allows for functions such as monitoring sludge overflow, stopping water discharge, and redirecting it back to the raw treatment process.

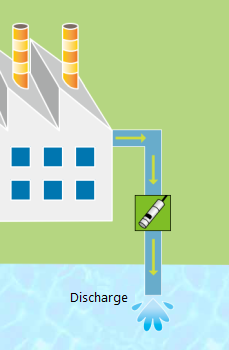

9) Water Outflow Monitoring

This enables final monitoring of treated water before it is discharged into the river.

10) Remote Turbidity Monitoring in Rivers

By integrating our sensors with NiGK Corporation’s solar-powered “aqua e monitor,” remote monitoring becomes possible even in locations like rivers where a power supply is unavailable. Measurement data is transmitted via email.

1) Mounting Attachment: TA-1 [Parts No.05039]

Mounting the turbidity and SS sensors onto a pipe helps prevent them from colliding with walls or facility equipment, and stops them from rotating—especially useful in fast-flowing water conditions.

Applicable Pipe: Stainless steel pipe (25A, OD 34 mm)

Material: S30400 Note: The installation pipe should be prepared by the customer.

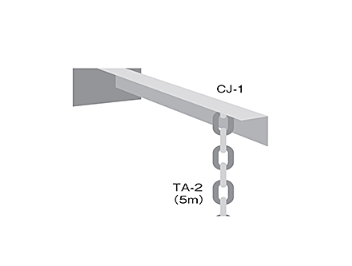

2) Support bracket: CJ-1 Hanging chain: TA-2

CJ-1 [Parts No.05033]

TA-2 [Parts No.05067]

It is a metal fitting for hanging the sensor.(CJ-1)

It is a chain for suspending the sensor.(TA-2)

3) Maintenance kit: TC-MK [Parts No.05038]

It is a replacement blade of the wiper cleaning device. Please exchange once a year as a guide.

Component

●Wiper blade × 2

●Cleaning brush × 1

●Detection window Cleaning paper × 2

●Manual × 1